16kN Heavy-Duty Steel Snap Hook for Industrial Fall Protection

- Model

- JS-2081

Item specifics

- Material

- Sheet steel, Heat treated

- Item number

- JS-2081

- Meets or Exceeds

- EN362-2004, ANSI z259.12-09, CSA z259.12-16

Review

Description

JS-2081 16kN Steel Snap Hook Description

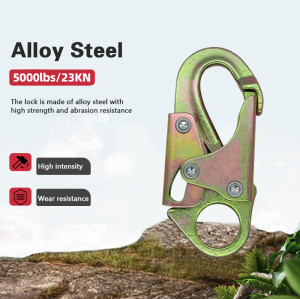

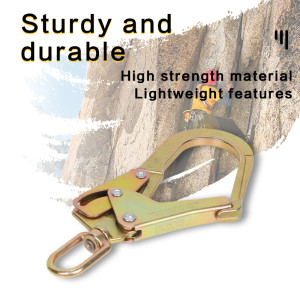

The 16kN Heavy-Duty Steel Snap Hook is engineered for industrial fall protection systems, providing a secure, durable connection point for safety harnesses, lanyards, rope access equipment, and rescue assemblies. Built from high-strength steel with a reliable spring-loaded gate, this snap hook delivers consistent performance under demanding work-at-height conditions.

Optimized for OEM safety harness manufacturers and industrial PPE brands, it balances strength, durability, and cost efficiency for large-scale system integration.

JS-2081 16kN Steel Snap Hook Parameters

Any Color (Can be customized) | Steel Snap Hook |

| Item number | JS-2081 |

| Material | Sheet steel, Heat treated |

| Packing size | Canton: 50pcs/ctn 36.5*26*12cm |

| Packing by | Mail box |

Available color | Any Color (Can be customized) |

Function | For construction sites, power facilities, miners, oil exploration, rock climbing and outdoor sports |

Professional JS-2081 16kN Steel Snap Hook Purchase Guide

1. Material & Durability

This snap hook is manufactured from high-strength forged alloy steel, specifically selected for industrial fall protection and work-at-height applications where durability and reliability are critical. The steel body undergoes precision forging and heat treatment, resulting in excellent resistance to deformation, impact, and long-term fatigue under repeated load cycles.

A corrosion-resistant surface treatment (zinc plating, electrophoretic coating, or optional galvanization) protects the snap hook from rust, abrasion, and chemical exposure. Compared with aluminum connectors, the steel construction offers greater impact tolerance and longer service life in harsh industrial environments.

2. Outdoor Environmental Adaptability

Designed for demanding outdoor job sites, this steel snap hook maintains stable performance in:

High humidity, rain, and wet working conditions

Dusty and abrasive construction environments

Temperature fluctuations in outdoor work-at-height scenarios

Coastal or industrial areas with corrosive atmospheres

The robust steel structure and protective coating ensure consistent functionality for construction safety, tower climbing, rope access, rescue operations, and industrial maintenance, even after prolonged outdoor exposure.

3. Load Performance & Safety Factor

With a minimum breaking strength of 16kN (≈1,600kg), this snap hook is engineered to meet the requirements of industrial fall protection systems and safety harness assemblies. The load-bearing structure is optimized to distribute forces evenly, reducing stress concentration during dynamic events such as fall arrest.

The snap hook is compatible with international safety standards including EN 362 and ANSI Z359, and is designed with an appropriate safety factor for both static positioning and dynamic fall-protection applications. Each unit can be laser-marked with load rating and batch traceability, supporting PPE certification, inspection, and quality audits.

4. Structural Craftsmanship & Detail Finishing

Precision manufacturing ensures consistent quality across mass production:

Ergonomic hook geometry for smooth connection to D-rings, lanyards, and anchor points

Rounded internal contact surfaces to minimize wear on ropes and webbing

Reliable spring-loaded gate mechanism for secure closure and smooth operation

CNC-controlled deburring and polishing to eliminate sharp edges

Uniform surface finish for enhanced corrosion resistance and professional appearance

OEM/ODM options include locking styles (standard, screw lock, double lock), custom surface treatments, laser-engraved logos, and dimensional adjustments, allowing seamless integration into branded industrial safety harness systems.

Want to know more product information? Click to contact us and you will get professional equipment guidance